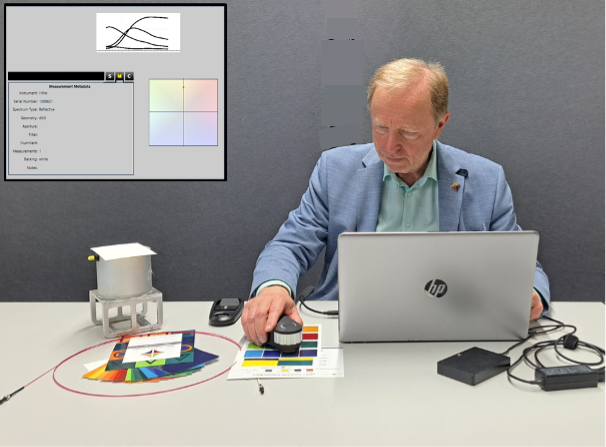

The aCRL®.academy Europe offers awareness training with aCRL®.colors and shapes in a personal and professional context. The current aCRL®.colors and shapes were developed in an optimization process and are subject to constant quality control. (see Fig. F1)

R&D projects are carried out in parallel to continuously review the aCRL® methods and tools as well as new applications. The following topics are currently the focus of attention:

Prof. Dr.-Ing.

Physics, Optics

Head of Research

M.Ed. Physics & Mathematics

aCRL® Development & Teaching

Fig. F1: Measuring stations for color characterization and quality control, and typical measurement examples

aCRL®.colors and gray forms are subject to continuous quality control. A commercial color measuring device or a fiber optic color measuring prototype is used for analysis and documentation. The color values and the distances derived from them are measured to an aCRL®.standard.

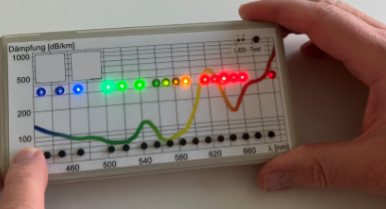

Fig. F2: Representation of the possible center wavelengths of typical light-emitting diodes (LEDs) as a function of wavelength in the visible wavelength range and the attenuation curve of a polymer fiber, as of 2010 /1/

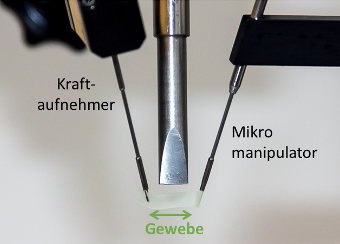

Fig. F3: Arrangement for measuring the fluorescence of tissue that is moved by micromanipulators with nano-forces /3/

Fig. F4: Fiber optic prototype with a special arrangement of optical fibers for controlled light detection /3/

/1/ LED prototype for teaching in the field of fiber optics, developed by POFAC at Nuremberg Tech

/2/ M. Brandenburger, J. Wenzel, R. Bogdan, D. Richardt, F. Nguemo, M. Reppel, J. Hescheler, H. Terlau, A. Dendorfer, “Organotypic slice culture from human adult ventricular myocardium,” Cardiovasc Res. 93(1), 50-9 (2012).

/3/ M. Belz, A. Dendorfer, J. Werner, D. Lambertz, K.-F. Klein: “Fiber Optic Biofluorometer for Physiological Research on Muscle Slices”; Proc. of SPIE Vol. 9702, 97020Q (San Francisco, Jan. 2016)